Introduction:

Currently, the ready-made garment is one of the components of the textile industry. On the other hand, a ready-made garment is not complete without a sewing process. However, indeed sometimes we do not get the expected results in this category. There are several reasons behind it.

Why quality defect occurs and what is done in the industries:

- Quality defects can be due to a lack of proper skills, equipment disruption, and improper repair of equipment. If the defects are not identified on time, then it can have an adverse effect on the quality, production, cost, and efficiency of the product.

- Quality standards that are set by the buyer and the factory are therefore part of the production process, product development, and production planning. Standards reflect the overall internal quality the company seeks to achieve. The primary purpose of using these quality standards is to provide consistency between products and product lines.

- But still in the textile industry errors are a common phenomenon that disrupts the smooth production rate and these low-quality products have an impact on the overall economic performance of the industry. Error reduction is required for quality improvement and productivity.

- Re-work is done in case of low-quality products and it ultimately lowers productivity. Reworks are non-value added activities and the customers are not willing to pay for it.

- To prevent low-quality products it is necessary to first find out the errors and then find the best solution to reduce or eliminate them. Standard Operating procedure (SOP) should be properly maintained and followed in every stage of production.

How the quality of the garment is ensured?

After a garment is produced, it is very important to ensure the proper quality of the garment. The produced garment must meet the criteria set by the buyer. To ensure the quality of the garment, two types of systems are followed:

1. Testing

2. Inspection

Here, we are going to talk about inspection only.

What is Garment inspection?

The inspection is done to control the quality of the garments by checking in bare eyes. Checking the fabric of the garments, button, thread, zipper, measurements of the garments, etc. with the standard process is called inspection.

The quality defects that are identified during garment inspection is discussed below:

Types of quality defect:

Broadly speaking there are 3 types of quality defects.

- Minor defect

- Major defect

- Critical defect

1. Minor defect:

These are those defects that do not affect the function or form of the garment. Customers will probably never notice the defect. There is no chance of garment return.

Example:

Bottom curl part within .5”

Uneven stitching

Loose thread

Untrimmed thread

Care label quality issue

Minor shade variation

2. Major defect:

These are those defects that affect the appearance of the garments. The customer may notice the problem and may also return the product. Generally, the buyer allows a few garments with a major defect.

Example:

Uncut thread

Skip stitch

Spot

Bottom curl part more than .5”

Holes

Broken stitch

Zipper not working properly

Incorrect stitch per inch (SPI)

Bubbling (Fusing defect)

Incorrect color or design

3. Critical defect:

These are those defect that makes the product unusable or the product become harmful for the customer. Buyers show ‘zero tolerance’ towards critical defects.

Example:

Child item which has not covered minimum neck stretch.

Blood stain of the worker due to sharp object.

Presence of broken needle or sharp object

Insect or mildew in garment folds.

Button half stitch

Button stitching is not strong enough

Extremely loose thread or trims.

Missing proper labels

Button sharpness

Azo dye (causes itchiness and very harmful for the skin)

12 major quality defect found in finished garments:

Open/broken seam:

A certain portion of the garment has not been sewn.

|

| Open seam |

Causes:

- Improper handling of garment parts.

- The needle and looper (for chain stitch)/hook (for lock stitch) setting is not done properly.

Remedies:

- Match the parts of the garment properly before sewing.

- Maintain proper tension of the thread.

- Maintain proper timing of needle and looper/hook.

Broken stitch:

The sewing is non-continuous.

|

| Broken stitch |

Causes:

- Any problem with the machine.

- The thread cutter is not working properly.

- Thread breakage due to heavy tension.

Remedy:

- Check the machine regularly, make sure the needle plate, pressure foot, feet dog are in a proper position.

- Check if the thread cutter is working properly.

- Thread tension must be maintained properly.

Also read: Fabric consumption calculation of a polo shirt | How to calculate fabric consumption of a polo shirt

Uncut/loose thread:

The thread is not cut properly.

|

| Uncut thread and loose thread |

Causes:

- The thread trimmer is not working properly.

- Lack of attention of the operator.

- Thread sucking machine fault. (Thread sucking machine is a special machine that is meant to suck all the dust and loose thread from the finished fabric)

Remedy:

- Properly press the trimmer.

- Check the thread trimmer frequently.

- Double-check the garment before packing.

Seam slippage:

The yarn of the fabric comes out of the seam.

|

| Seam slippage |

Causes:

- It mainly happens if the fabric is slippery and made out of continuous filament yarn.

- Due to improper stitch length and seam width.

Remedy:

- Try to use French seam.

- Decrease stitch length.

- Increase seam width.

Drop stitch/skip stitch:

Irregular stitching along the sewing line.

|

| Drop stitch or skip stitch |

Causes:

- The machine is not working properly.

- Improper handling of the cut panels.

Remedy:

- Proper adjustment of all the machine parts, especially needle, thread, pressure foot, feed dog.

- The needle must be placed properly.

- Tension must be maintained properly.

- Handle the cut panels with care.

Twisting:

The front part and back part pattern do not match. As a result the finished garment also becomes asymmetrical.

|

| Twisting |

Causes:

- Defective fabric cutting.

- Defective fabric bundling.

- Defective panel matching.

Remedy:

- While cutting and bundling the fabric, the same size must be bundled together.

- Before sewing, double-check must be done by the person who is matching the front and the back part.

Raw edge:

The edge fabric is not cut after sewing.

|

| Raw edge |

Causes:

- The operator is not paying enough attention.

Remedy:

- The operator who is doing the final checking must be extra careful.

Seam puckering:

Gathering of fabric right after sewing or after washing.

|

| Seam puckering |

Causes:

- Uneven stretching of plies during sewing.

- Uneven shrinkage of different plies after washing.

- Improper thread tension.

Remedy:

- Make sure different plies of fabric are evenly stretched during sewing.

- Maintain proper thread tension.

- A proper shrinkage test of different fabrics should be done.

Curl part:

The end of the garment does not match properly.

|

| Curl part |

Causes:

- Due to improper cutting.

- Due to unequal seam width.

Remedy:

- While cutting the fabric, make sure it matches the size appropriately.

- The seam width should be maintained properly.

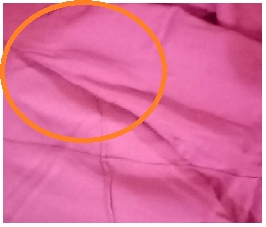

Pleating:

Unwanted fold in the seam area.

|

| Pleating |

Causes:

- Improper handling of the garment while sewing.

- Improper tension.

Remedy:

- During the sewing process, the operator must make sure that the garment is laid flat.

- Tension must be maintained properly.

0 Comments