What is sewing thread consumption?

sewing thread consumption is the total length of thread required to produce a particular garment of particular size.

Why thread consumption calculation is needed?

- A garment is produced by stitching all the cut panels together. For stitching, we need sewing thread.

- To do the costing of a garment properly, we need to identify how many meters of sewing thread will be required to produce the garment. Wrong thread consumption calculation will lead to wrong cost calculation of a garment. Generally, a medium-sized t-shirt requires 120 m of sewing thread. But it varies depending on the type of machine, style of the garment, seam width, Stitch per inch (SPI), waste, and many other factors.

Types of machines required for manufacturing t-shirt:

There are 3 types of machines required for t-shirt manufacturing. They are-

1. Single needle lock stitch machine (plain machine)

Stitch type: 300

2. Overlock machine

Stitch type: 500

3. Flat lock machine

Stitch type: 600

How to calculate sewing thread consumption?

Sewing thread consumption can be done in two steps, one is overall sewing thread consumption and the other one is separate needle and looper thread consumption calculation. Here, we shall discuss both of them.

Sewing thread consumption formula with an example:

Let us consider a t-shirt with the following stitch length measurements:

|

| Stitch length measurement chart |

The ratio chart for a t shirt:

|

| T shirt ratio chart |

Also read: Costing of garments formula | How to determine costing of a t-shirt

Calculation:

For the parts where SNLS (plain m/c) is used:

Label

+ Front neck top stitch + Back yoke moon patch + (Sleeve tuck*2)

[As

there are two sleeves so sleeve tuck has to multiplied by 2]

Now,

10+22+32+(5*2)

cm = 74 cm

Ratio

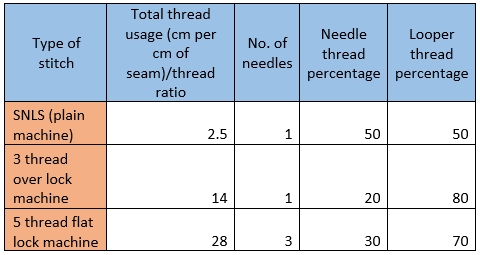

= 2.5; needle thread % = 50; Looper thread % = 50

So,

Total thread requirement for SNLS = (74*2.5) cm = 185 cm

Needle

thread requirement = 92.5 cm

Looper

thread requirement = 92.5 cm

For the parts where over lock machine is used:

(Side

seam*2)+Shoulder join+(Sleeve join*2)+Neck join

Now,

(55*2)+25+(48*2)+52

= 283 cm

Ratio

= 14; needle thread % = 20; Looper thread % = 80

So,

Total thread requirement for over lock = (283*14) cm= 3962 cm

Needle

thread requirement = 792.4 cm

Looper

thread requirement = 3169.6 cm

For the parts where flat lock machine is used:

(Bottom

hem*2)+(Sleeve hem*4)+Back neck top stitch+ Shoulder top stitch

Now,

(50*2)+(18*4)+25+25

= 222 cm

Ratio

= 28; needle thread % = 30; Looper thread % = 70

So,

Total thread requirement for over lock = (222*28) cm= 6216 cm

Needle

thread requirement = 1864.8 cm

Looper

thread requirement = 4352.2 cm

So, Total thread requirement = (185 + 3962 + 6216) cm

= 10363 cm + 15% allowance

= 11917.45 cm

= 119 m

Conclusion:

Proper

thread consumption identification is a must for proper costing of garments. Generally,

companies have their very own excel format ready to find out thread consumption

easily.

0 Comments