Lab dip program, sample fabric program and development sample program are 3 programs that a merchandiser must produce and those should get buyer's approval.

Development sample program:

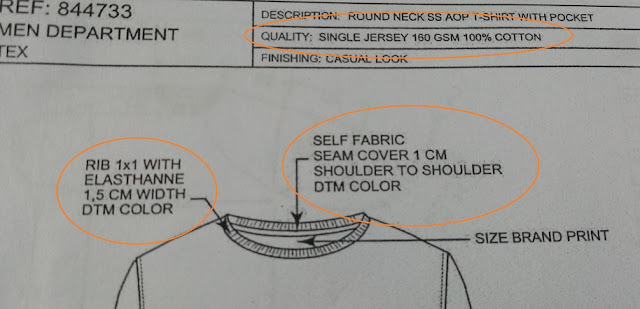

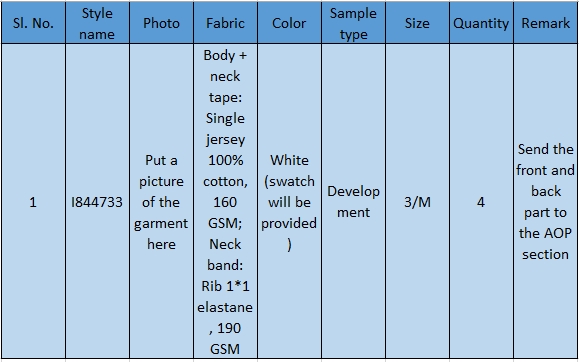

This is the last of the three sample programs. Here the factory produces some pieces of garments (usually 4) following all the requirements of the buyer. The buyer mentions the size of the sample in the techpack. The development sample will maintain that size. If the style has printing or embroidery work on it, the sample should also follow those. Also, any kind of special mention (like- ironing, washing) should also be followed.

Information needed to produce a development sample program are-

(All information can be found on the techpack.)

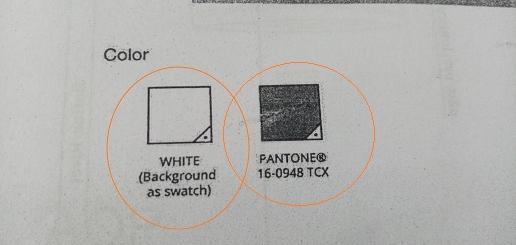

The base color and the print color both can be known from the second page where all the design details of the garment is provided.

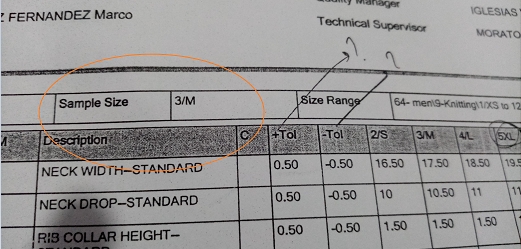

The sample size that needs to be produced for development sample is mentioned on the measurement page.

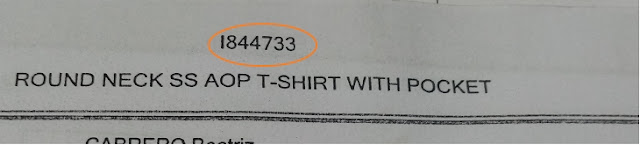

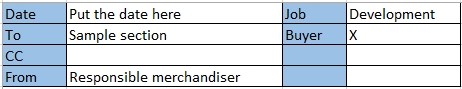

An example of development sample program is presented here:

Development sample program for company 'X'

Note: If the garment has printing, AOP work then remark it must be mentioned. Because generally after the production of fabric, it goes through softening process. Softening improves the handfeel of the fabric but reduces its dye absorbency. So, in the case of printing, AOP the fabric goes through softening process afterwards.

In case of embroidery, it is done on garment panel before sewing. So if the fabric has embroidery work on it, it should also be mentioned too.

These information are then sent to the sample section for producing development sample.

Then the garment is sent to the buyer for final approval. The approved sample is presented in the

pp meeting so that appropriate garment can be produced during bulk production.

0 Comments