Lab dip program, sample fabric program and development sample program are 3 programs that a merchandiser must prepare and those should get buyer’s approval.

Sample fabric program

Sample fabric program is sent to the knitting and dyeing

department. A specific quantity of fabric (7-8 kg) is prepared and dyed

according to sample fabric program that follows the requirement of the buyer

and then the sample fabric is sent to the buyer for approval.

Information needed to produce a sample fabric program are-

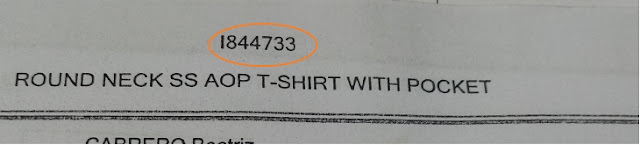

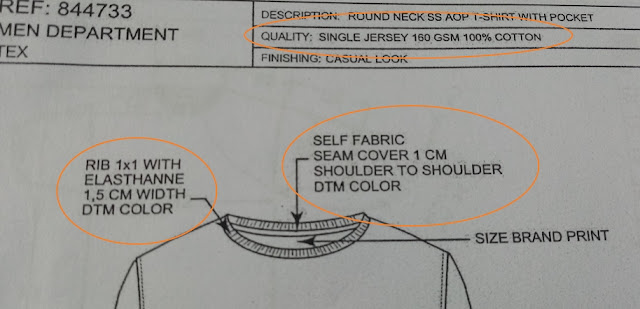

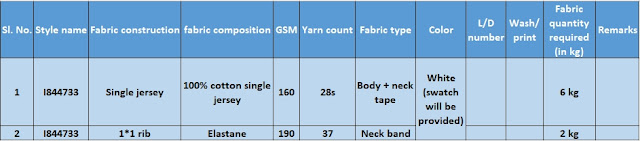

fabric construction, fabric composition, GSM, fabric type all information can be found from here.

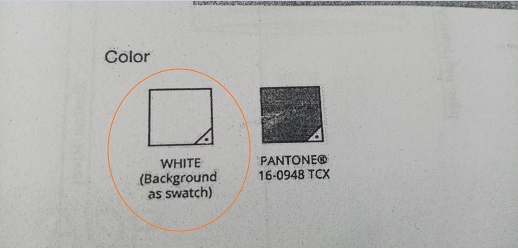

Information on the color of the garment can be found from the second page where garment print/embroidery related information are given.

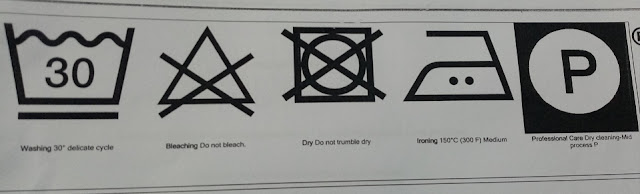

Garment care related information can be found at the last page.

An example of sample fabric program is presented here:

Sample fabric program for company 'X'

1. Washing at 30 degree delicate cycle.

2. Do not bleach

3. Do not tumble dry.

4. Ironing at 150 degree (medium)

5. Professional care dry clean mid process P.

Quality requirements:

1. Soft hand feel, clean surface.

2. Can be washed with similar color.

3. Color fastness to washing (Instructed will be given by the buyer)

4. Color fastness to dry (Instruction will be given by the buyer)

Garment Image:

Prepared by Checked by Approved by Received by

(The signatures will be placed here)

These information are then sent to the dyeing and knitting department for producing sample fabric.

Then the fabric is sent to the buyer for final approval. The approved sample is presented in the

pp meeting so that appropriate fabric can be produced during bulk production.

0 Comments