What is a bulletproof vest?

- Bullet vests are body armor that is specially designed to protect the vital organs of the wearer’s body from injury. These vests have a ballistic plate inserted into the vest. Special composite materials are used for the protective panel, additionally metal or ceramic panel can also be used to provide additional protection.

- Soft vest that has a metallic layer or tightly woven fabric layers can only provide resistance to stab and slash form knives but it cannot stop the bullet.

Raw materials:

- The main raw material of a bulletproof vest is a ‘KEVLAR’. It is a complex polymer that is made through polymerization.

- Cotton, polyester blend, or nylon is used for comfort in the inner side of the vest.

Kevlar:

Composition:

Kevlar is a synthesized solution of 1,4-phenylene-diamine (para-phenylenediamine) and terephthaloyl chloride. The reaction is a condensation reaction and hydrochloric acid is the byproduct. Hexamethylphosphoramide was initially used as the solvent for the reaction but later, due to safety reasons, DuPont started using N-methyl-pyrrolidone and calcium chloride as the solvent.

There are many different versions of Kevlar. Among them-

- Kevlar K129 has high tenacity and used for ballistic protection.

- Kevlar K149 has high tenacity and used for ballistic, armor and aerospace applications.

Raw materials:

- The main raw material of a bullet proof vest is a ‘KEVLAR’. It is a complex polymer that is made through polymerization.

- Cotton, polyester blend or nylon is used for comfort in the inner side of the vest.

Also read:

Difference between N95, KN95, surgical mask | What is N95 mask | What is KN95 mask | What is surgical mask

Why Kevlar?

- Kevlar is heat resistant and strong. But a fabric must have a high tenacity to be used in a bulletproof vest.

- Kevlar has very high tenacity. It is used for bulletproofing due to its ‘high tensile strength to weight ratio’. Also, it is measured to be five times stronger than steel. So Kevlar is a very effective material to be used for bulletproofing.

Process of making a bulletproof vest:

Kevlar production:

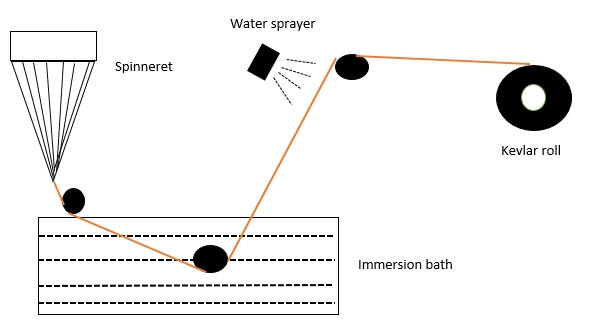

It all starts with the production Kevlar. Kevlar is produced in the polymerization process and the polymer is then extruded through a spinneret.

What is spinneret?

- It a metal plate with very tiny holes in it. Liquid polymer passes through the holes of the spinneret and takes the form of a continuous thread.

- After passing through the spinneret, the thread is still very hot and malleable. The thread then passes through a cooling bath where the thread hardens and the polymer structure becomes stable.

- Then the continuous thread is winded in a reel.

|

| Kevlar thread production process (simplified) |

Weaving process:

Before weaving, twist is incorporated in the yarn. Then the yarn goes for the weaving process. In most of the cases, plain weaning is done to make Kevlar cloth which is the simplest form of weaving.

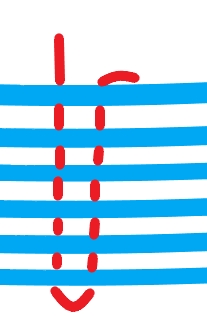

What is plain weaving?

It is a type of weaving in which the weft thread alternately goes over and under the warp thread. Plain weaving provides maximum surface coverage.

|

| Plain weaving |

Cutting process:

- After weaving, the fabric is sent to the manufacturing factory for cutting, sewing and finishing. For cutting a huge cutting table is needed because all the layers are needed to be cut at the same time to prevent any size variation. The table can be as long as 30 meters and the no. of Kevlar layers may vary from 8-25 depending on the level of protection.

- After placing all the cut pieces on the cutting table, a pattern piece is placed onto them. Then a computerized cutting machine or handheld straight knife and band knife are used to cut the fabric panels.

Sewing process:

Some bulletproof vests may have no stitches. The layers are cut, stacked and fused in such a way that it creates a pouch that fits perfectly on the wearer. But in most of the cases, sewing is done to hold the layers of the vests together. Kevlar thread is used for the sewing. Generally, 2 types of sewing are used:

1. Quilt stitch

2. Box stitch

1. Quilt stitch: This stitch holds different layers together.

|

| Quilt stitch (top view) |

|

| Quilt stitch (illustrated side view) |

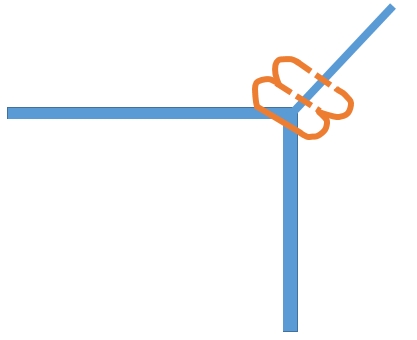

2. Box stitch: This is done along the sides of the vest.

|

| Box stitch (done on the sides) |

Finishing process:

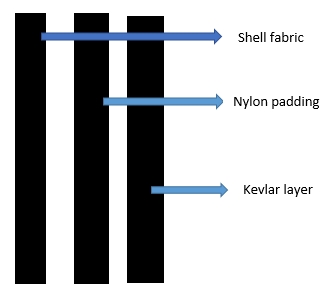

After the making of the main Kevlar panel, it is placed inside the shell. The purpose of the shell is to provide comfort as Kevlar fabric is very uncomfortable to wear.

The shell fabric can be a cotton-polyester blend. Also, absorbent materials can be used in the inside portion of the vest to provide some extra comfort. Nylon padding is also used to provide additional safety and comfort. Also various accessories, like buckles, velcro etc. are attached to the attached for proper closure.

|

| Layers of bulletproof vest |

Conclusion:

This vest then goes through a number of quality control procedures to ensure the quality. Developers are working hard to develop the quality of bulletproof vests and in the near future we can expect to get something that will provide us with even better performance.

0 Comments