What is lab dip sample?

Lab dip sample is a sample that is prepared to get color

approval from the buyer. Three 2 cm*2 cm samples are prepared according to the

requirement of the buyer. Each of these sample has a unique lab dip number.

After that, all three of these samples are sent to the buyer. The buyer choose

one of the samples and that sample is considered as the final sample. That

sample is presented in the pp meeting so that all the final product can meet

the requirement of the buyer.

The process of lab dip sample preparation:

- The Dark room:

This is the place where lab dip sample preparation starts.

There are a number of machines which are used to prepare the initial recipe for

the sample. After the production of lab dip sample, it is again sent to the

dark room for color approval.

Also read: Lab dip program |How to prepare a lab dip program | What are the information needed to write a lab dip program.

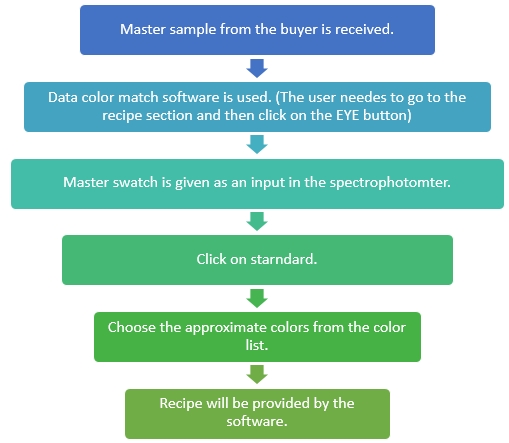

1. Data color match

This is an application installed in the computer of the

darkroom that is used to find out the initial recipe for preparing a particular

shade.

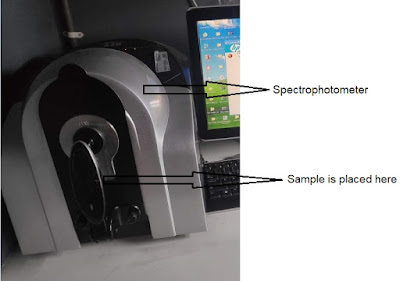

Data color match works incorporation with a

spectrophotometer.

The process flow chart is shown below:

|

| Recipe preparation in the dark room. |

|

| spectrophotometer |

Note: The recipe that is provided by the machine is not 100%

correct. This just gives an idea after that manual modification will be needed.

Because in most of the cases, washing or various after treatments are involved

that will change the color. So manual adjustments are done in the recipe

keeping all these things in mind.

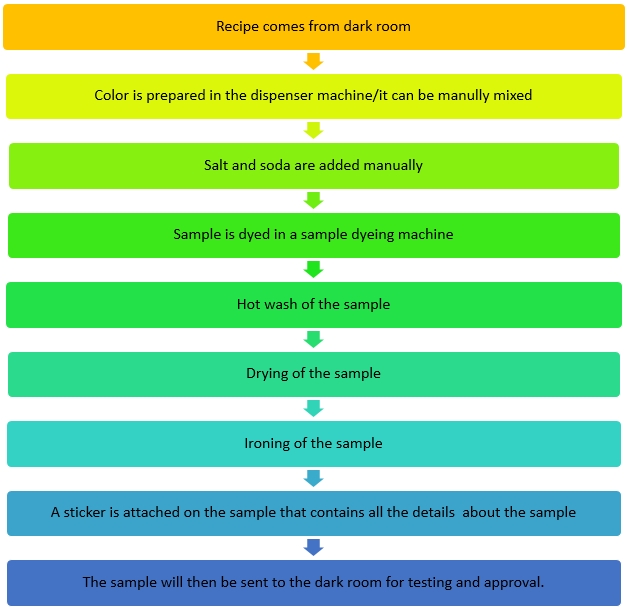

Sample dyeing room:

This is the room where lab dip sample is prepared. All the

machine needed for fabric dyeing are available here but they are small in size

and pretty basic in terms of functionality.

Process flow chart of lab dyeing:

|

| Lab dyeing process flow chart |

|

| Dispenser machine |

|

| Sample dyeing machine |

|

| Sample washing machine |

|

| Sample drying machine |

From the sample dyeing room, the sample then goes again to

the dark room for color matching.

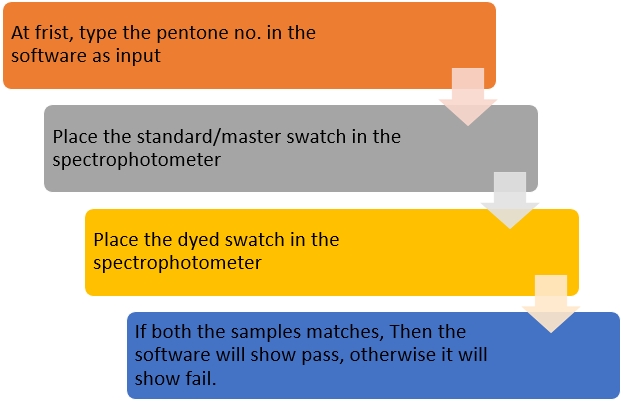

Data color software:

For color matching, data color tool software is used. Data color tool software also works incorporation with spectrophotometer.

The process is shown below:

|

| Lab dip sample checking process |

If the result is fail, then the software will show the

reason. It will also provide some recommendations, like- How to adjust the

color combination or which color is missing.

Light box test:

Every buyer wants their garment color to be checked under a

specific light. Under that light, the lab sample color should perfectly match

the master sample color. That’s why the final test in the dark room is the

light box test.

The type of lights in the light box are-

- D65 (Daylight, most commonly used by the buyer)

- Ultra 3000

- TL 83

- UV light (This is the light that is used when Optical brightening agent is added to the fabric. Fabric treated with optical brightening agent will glow under UV light.)

- F/10 light (This light is used to check metamerism in the fabric)

What is metamerism?

If two colors are not exactly the same (they reflect

different wavelength of light) But under certain lighting condition if they

appear the same, then this phenomena is called metamerism.

After all these checking, if the sample gets approval, then

it is sent to the lab for further testing.

0 Comments